Why Plants Don’t Fail Because of Bad Tech—They Fail Because of Data You Can’t Trust

And how digital calibration saves you from “audit apocalypse.”

Let’s get one thing straight:

Most plants don’t fail because of bad technology.

They fail because of data they can’t trust.

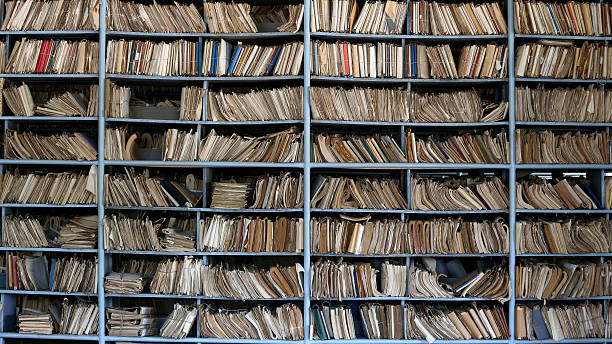

We’re talking calibration records written like your doctor’s prescription pad—half in millivolts, half in voodoo. One loop reads in “PSI,” the next one says “yesterday.” And don’t even get me started on the logbooks that look like they lost a fight with a cup of coffee and a Sharpie.

True story: I audited a site once…

…where calibration records were stored in a milk crate.

Yes. A milk crate. Not a server, not SharePoint.

Not even an Excel sheet.

The labels were peeling, numbers were crossed out and re-written 3 different times, and one record literally said, “Looks good – Bob.” No date. No signature. Just Bob’s good vibes.

I turned to the Maintenance Manager and asked,

“Out of curiosity, what happens if the FDA shows up tomorrow?”

He looked at me, blinked twice, and said:

“We pray they don’t.”

The calibration data crisis is real.

Your techs are out there doing the work—loop checks, pressure calibrations, temp sensors—but if the data trail is broken, incomplete, or sketchy, you’ve got a compliance liability on your hands.

Think about it:

- Can you prove a calibration happened?

- Can you show who did it, when, with what reference standard?

- Can you pull a report in 5 minutes or less?

If the answer is “maybe,” “I think so,” or “call Bob,” you’ve got a trust issue… and a potential production-stopping, audit-failing, career-sinking problem.

Let’s talk about the fix: Digital Guided Calibration

You don’t need to burn the place down and start over.

You just need to get serious about the data trail.

Here’s how digital calibration changes the game:

1. Smart Calibrators with Digital Memory

Beamex MC6 isn’t just a calibrator—it’s your technician’s new best friend. It timestamps every action, locks in measurements, and captures everything from as-found/as-left readings to work instructions—no handwriting required. (Even Bob can’t mess it up.)

2. Tamper-Proof Audit Trails

You can’t “accidentally” delete a Beamex calibration. Everything is logged, secure, and traceable. The Beamex solution helps you become “audit-proof”.

3. CMX or LOGiCAL Integration

No more siloed spreadsheets, paper logs, or black-hole file shares. You get one clean, searchable database that shows everything you need to pass an audit or sleep at night.

4. Analytics That Actually Work

Why wait for a failure when you can spot drift trends before they shut down your process?

The right dashboard shows you which loops are moving out of tolerance so you can fix it before it becomes a “root cause analysis” nightmare.

But wait, Josh—what about training?

Good news: Beamex’s guided calibration process makes onboarding new techs faster.

The device tells them what to do, in what order, with step-by-step instructions.

It’s like having your best technician riding shotgun on every calibration.

(Without actually having to ride shotgun. That’s weird.)

Bottom line: You don’t have a calibration problem. You have a data problem.

And the solution isn’t more headcount, more binders, or more “Bob.”

It’s a digital calibration ecosystem that locks in your data, syncs it across your team, and gives leadership the confidence to trust what’s happening in the field.

Because if your data can’t be trusted…

Your process can’t be trusted.

And if your process can’t be trusted…

Well, you’re one failed audit away from your next job posting.

Let’s fix it before it breaks.

Step 1: Start small — pilot one loop, one shift, one crew. Pick a critical loop that keeps you up at night (think: pressure control to the reactor, level to the tanks). Run a 30–60 day pilot with digital guided calibrators and CMX/LOGiCAL integration. Measure time saved, number of corrected entries, and how fast you can pull reports. You’ll be surprised how quickly the pilot converts skeptics into evangelists.

Step 2: Quick wins to show leadership Use these measurable wins to justify rollout: - Reduced audit prep time (minutes, not days). - Fewer repeat calibrations because data’s clear. - Faster onboarding — new techs hit competency quicker. - Early detection of drift — less unplanned downtime. Even a conservative plant can see ROI in months when you stop wasting hours chasing paper.

Overcoming the Top Objections (with straight talk) -

“It’s too expensive.” — False. The cost of one production outage or one failed audit more than covers the system. Add time-savings and fewer repeat fixes, and the math gets friendlier fast. -

“Techs won’t use it.” — If it’s faster and removes guesswork, they’ll love it. Guided steps reduce prideful improvisation (“Bob’s method”) and increase consistency. -

“We’ll lose flexibility.” — You’re not locking people into a script; you’re giving them the right data to be flexible and effective. A simple calibration readiness checklist

- Identify top 10 critical instruments by risk/impact.

- Map current calibration frequency and methods.

- Run a 30–60 day digital pilot on 1–3 critical instruments.

- Validate data integrity and audit-report speed. - Train one super-user per shift to scale adoption.

- Roll out in waves, prioritize high-risk areas. Real-world payoff (short anecdote) One plant I worked with cut their audit prep time from 48 hours to 20 minutes. The difference? Replacing hand-scrawled records with guided calibrators and a searchable CMX. The auditor asked for the same report twice — the tech sent it while the auditor was still reading. It was the shortest audit they’d seen in years.

Final thought — trust is operational resilience Techs fix transmitters, managers manage risk, and leadership needs confidence. Digital guided calibration ties it all together: reliable data, clear accountability, and a traceable trail that auditors actually appreciate. If you want to stop praying for auditors and start proving your process works, start with your data trail. Learn more.